Fabrication Technology Technologies

We have realized mass production of large diamond plates by our unique manufacturing technologies, which comprise the separation technique with ion-implantation and the fabrication of mosaic wafers by tiling of single crystal diamond plates

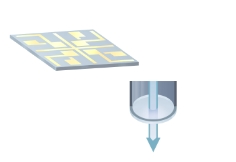

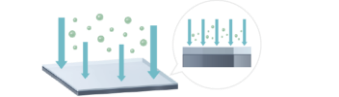

Separation technology using ion-implantation

For creating a single crystal diamond by CVD process, a substrate of single crystal is needed as a seed crystal. It is necessary to slice off in order to take a grown crystal away from the seed because there is no apparent border between them. However, it is not easy to comlete the slicing process especially on large size. Therefore, we employ the Ion-implantation technique, by which carbon cations are injected into surface of a seed before crystal growth and a collapsed crystal layer is created just below the surface. It is possible to grow a single crystal diamond on the seed because the outermost surface maintains crystal stucture of diamond. After the growth, we remove the collapsed layer electrochemically in order to obtain a fabricated single crystal diamond as a plate-shape. A part of the seed is lost during the separation process, however, the thickness of the lost part is just approx. 1µm. We obtain several clone single crystal diamond plates by repetation of the above process on a seed.

Seed crystal

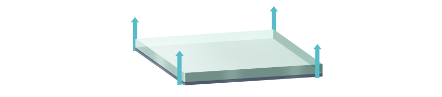

ion-implantation

CVD process / Microwave plasma enhanced chemical vapor depositon

Separation of a grown layer / Electrochemical etching

Growth to proper thickness / thickness < 3.0 mm

Polishing as needed

Cutting for product sizes

Manufacturing technologies of large square mosaic crystals

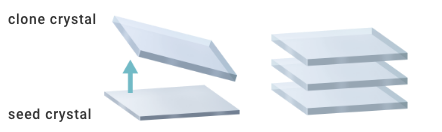

Single crystal plates have a limitation of their dimension. In order to create a larger plate, we have developped a complex substrate called "Mosaic crystal" which consists of several single crystals. We can fabricate single crystals with aligned crystal faces by duplication from an idetical seed crystal. Overgrowth on arranged clone crystals results in the fabricatoion of a "mosaic crystal", which is nearly borderless.

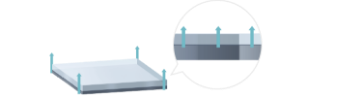

Production of several clone crystals from an identical seed crystal

Fabrication of several clone crystals from an identical seed crystal using the seperation technique.

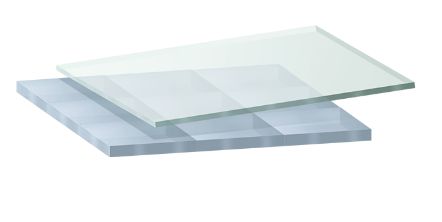

Vapor phase growth on closely arranged clone crystals

A well-coaleased grown layer is obtained by tiling the clone crystals copied from an identical seed crystal.

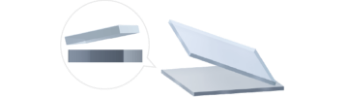

Separation of a grown layer / Electrolytic chemical etching

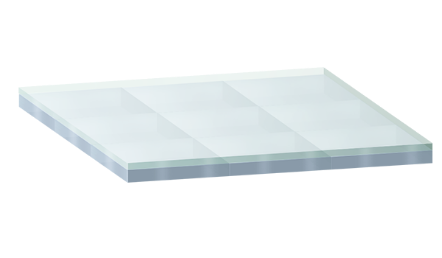

A mosaic crystal, which is nearly borderless, is obtained after separation of the grown layer.

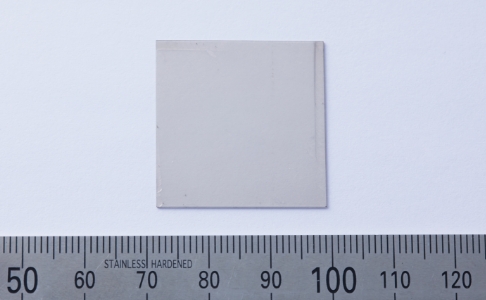

This is our 30x30mm mosaic crystal which consists f 9pcs 10x10mm single crystals. Customers can treat a mosaic crsytal as a large single crystal

We have achieved production of 1 inch / 25x25mm substrates using the mosaic crystal and the separation technologies. We plan to develop further large ones in future, such as 2 inches / 50x50mm substrate.

Contact Us

Please feel free to contact us about EDP

technology and products.